Dynautics provides Vessel Control System (VCS) and autopilot technology that seamlessly integrates into third party drive and motor control systems. We work closely with USV manufacturers to ensure that onboard control systems and their complex integration protocols are robust, efficient and above all provide optimal functionality and redundancy. Tell us your mission.

A selection of VCS missions that we have successfully completed for our customers are detailed below.

Triple engine control for Singapore Navy

Mercury outboard engines – credit Mercury

In 2021 Dynautics became a Mercury Marine dealer, giving us direct access to the company’s G3 engine set up software which is a critical factor in calibrating and optimising engine performance. This was quickly followed by an opportunity to work on a triple Mercury engine (900hp) VCS for the Republic of Singapore Navy’s uncrewed security and surveillance craft.

It was a challenging project with a tight timeframe, but by leveraging our experience with Mercury’s control protocol we were able to deliver our MK4 autopilot with Mercury interface module, remote control handset, wiring harness and Dynautics Remote Control Windows (RCW) application for remote route planning. All equipment was fully installed, calibrated and subject to sea trials in time for the Navy’s mission.

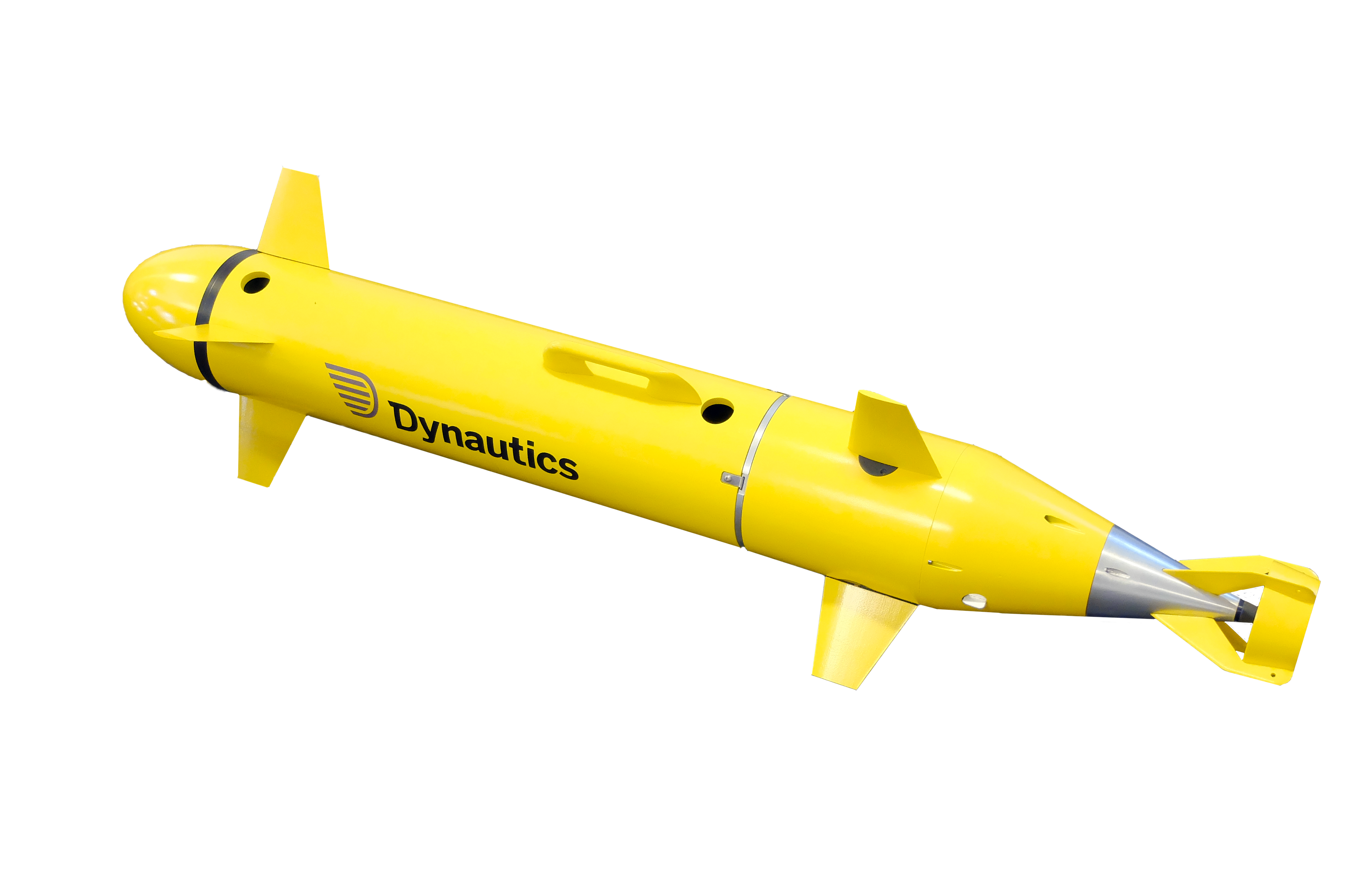

From clouds to waves with SPECTRE

SEA-X USV – credit ALTI

ALTI, a world-leading provider of VTOL aircraft based in South Africa, serves the civil and military sectors with UAVs (unmanned aerial vehicles) for commercial and industrial applications. In 2022, the ALTI team embarked on a mission to bring their 10 years of experience and hard-won expertise on unmanned aircraft operations around the world to the design of a marine USV.

Due to the ambitious timeline of the project, the team needed a control solution that they could fit themselves. Dynautics delivered a SPECTRE MK4 VCS, complete with wiring harness, interfaces and all necessary components that was ready to install. This plug and play solution dovetailed into ALTI’s existing communications system, giving the team a clear development and delivery path. Diagnostics took place remotely to progress the retrofit installation. Read the case study.

Royal Navy vessel conversions

Dr Alison Little

In its drive to leverage autonomous technology in the future of naval operations, the UK’s Royal Navy is converting some of its vessels to have unmanned functionality. This cost-effective development approach allows them to make use of commercial electronics and low NRE (non-recurring engineering) costs, speeding up the time it takes to get uncrewed craft operational.

The Royal Navy has, to date, placed two VCS orders with Dynautics. Dr Alison Little, senior project engineer at Dynautics, developed custom vessel control firmware for their unique behaviour requirements. Dynautics’ marine simulators were also used to reduce the development cycle and time to launch.

“Customers who have very specific operational needs make my job incredibly interesting. The team here thrives on solving technically demanding control problems. The Royal Navy needed very specific behaviour and I was able to simulate their requirement and code it quickly, which was incredibly satisfying.” Dr Alison Little, Dynautics

Precise drive control for RC Dock Engineering

Netherlands-based RC Dock Engineering enlisted Dynautics for the remote control of a 12m catamaran vessel, the first of 20 new remotely controlled unmanned workboats developed by the company, with azimuth thrusters and twin water jets.

RC Dock’s unmanned workboat

As well as designing the VCS using SPECTRE autopilot, Dynautics also advised on overall system architecture, design and the purchase of ancillary parts. We developed custom CAN communication firmware to provide precise control of the drive system and collision avoidance software was optimised with radar partners Simrad and Cambridge Pixel.

With RC Dock Engineering’s new hull design, transmission and power management arrangement, agility and collaboration were key on this project. The catamaran has since been granted RINA class approval. These automated vessels are able to conduct remotely controlled unmanned operations in areas such as offshore survey and subsea inspection, maintenance and repair.

Pushing boundaries with SEA-KIT

USV ‘Maxlimer’ – credit SEA-KIT

SEA-KIT International is a leading designer and builder of USVs with a range of applications across the offshore, survey, research, defence and security sectors.

In August 2020, SEA-KIT’s USV ‘Maxlimer’ took part in a collaborative Atlantic survey project, co-funded by the UK Space Agency. The project was designed to demonstrate true, over-the-horizon survey capability, testing cutting-edge, innovative technologies to survey unexplored or to-date inadequately surveyed ocean frontiers. The USV spent 22 days offshore, completing survey operations off the European continental shelf.

During the mission SEA-KIT’s ‘Maxlimer’ travelled over 1200 nautical miles and mapped over 400 square miles of previously uncharted ocean floor. Dynautics provided 24/7 project support to SEA-KIT’s Remote Operation Centre in Essex, UK.

“Dynautics proved to be a very capable and trustworthy, assisting us in the development of our product, bringing a wealth of experience and showing real commitment to meet deadlines during the pandemic.” Peter Walker, Director of Technology at SEA-KIT