Dynautics provides Vessel Control System (VCS) and autopilot technology that seamlessly integrates into third party drive and motor control systems. We work closely with USV manufacturers to ensure that onboard control systems and their complex integration protocols are robust, efficient and above all provide optimal functionality and redundancy. Several recent projects are outlined below. Why not get in touch and tell us your mission?

Autopilot for rim-driven thruster USV

Dynautics delivered an autopilot control solution with which to integrate new rim-driven thruster technology into HydroSurv’s vessels. The solution dovetailed into HydroSurv’s existing systems, giving a clear development and delivery path to install the technology on future vessels. Dynautics made extensive use of its automated simulation and testing product suite, so that the new control system was thoroughly trialled prior to delivery to HydroSurv. Read the full case study here.

“Our partnership with Dynautics has been instrumental to HydroSurv’s product development journey since we entered the USV market in 2019. The third-generation REAV-47 and REAV-25 platforms are the result of close collaboration with our customers and draw on over five years of experience in delivering USV solutions that drive immediate value for survey contractors. We’re excited for a strong pipeline of USV deliveries in 2025, with Dynautics playing a key role in supporting this next phase of deployment.”

David Hull, HydroSurv CEO

Controlling wave-propelled USVs

Dynautics has worked with AutoNaut since 2013, supplying customised platform control systems for their wave-powered USVs, with low power satellite communications and autopilot systems to control direction and follow mission plans. Dynautics also designed a bespoke system that manages battery charging from photovoltaic panels and the power supply for instruments and communications. This ‘power generation controller’ is designed to provide remotely monitored and remotely resettable circuit breakers which swiftly protect the system in the event of overload in any circuit. The whole control system is designed to use very efficient, low power processor boards, to optimise the use of solar energy. Read more here.

The AutoNaut Oban USV completed a groundbreaking mission to recover data from a Sonardyne seabed sensor located 1,800 metres underwater in the Rockall Trough, in the Atlantic Ocean northwest of Scotland and Ireland. Operated remotely via satellite, the wave-propelled vessel acted as a zero-carbon communications gateway to collect deep sea data for scientists onshore at the Scottish Association for Marine Science, and enabled them to recalibrate the instrument via satellite. The image shows AutoNaut Oban entering Penzance after 115 days at sea, covering more than 4000 nautical miles gathering data on the Atlantic shelf break.

Tracking the sun with floating solar

Collaborating closely with Noria and working to a tight timeline, Dynautics customised its existing autopilot and control solution for the AquaPhi prototype on a 10m-by-10m floating array with eight thrusters. The control system regulates the power supplied to each motor and direction of thrust to counteract wind and water currents. Thanks to some custom coding, developed by the Dynautics team, the solar array can also be programmed to stay in one location and rotate about its vertical access to track the sun, producing up to 20% more energy throughout the year and optimising site operations with easy repositioning of the array on the water. Read more here.

“Dynautics had the expertise and willingness to provide a customised solution for our floating solar tracker. Their team was very responsive and easy to work with, helping us meet tight deadlines and troubleshoot issues for this novel application of their control technology. The result is a product that will provide more energy and value to our customers.”

Jimmy Raiford, Head of Technology, Noria Energy

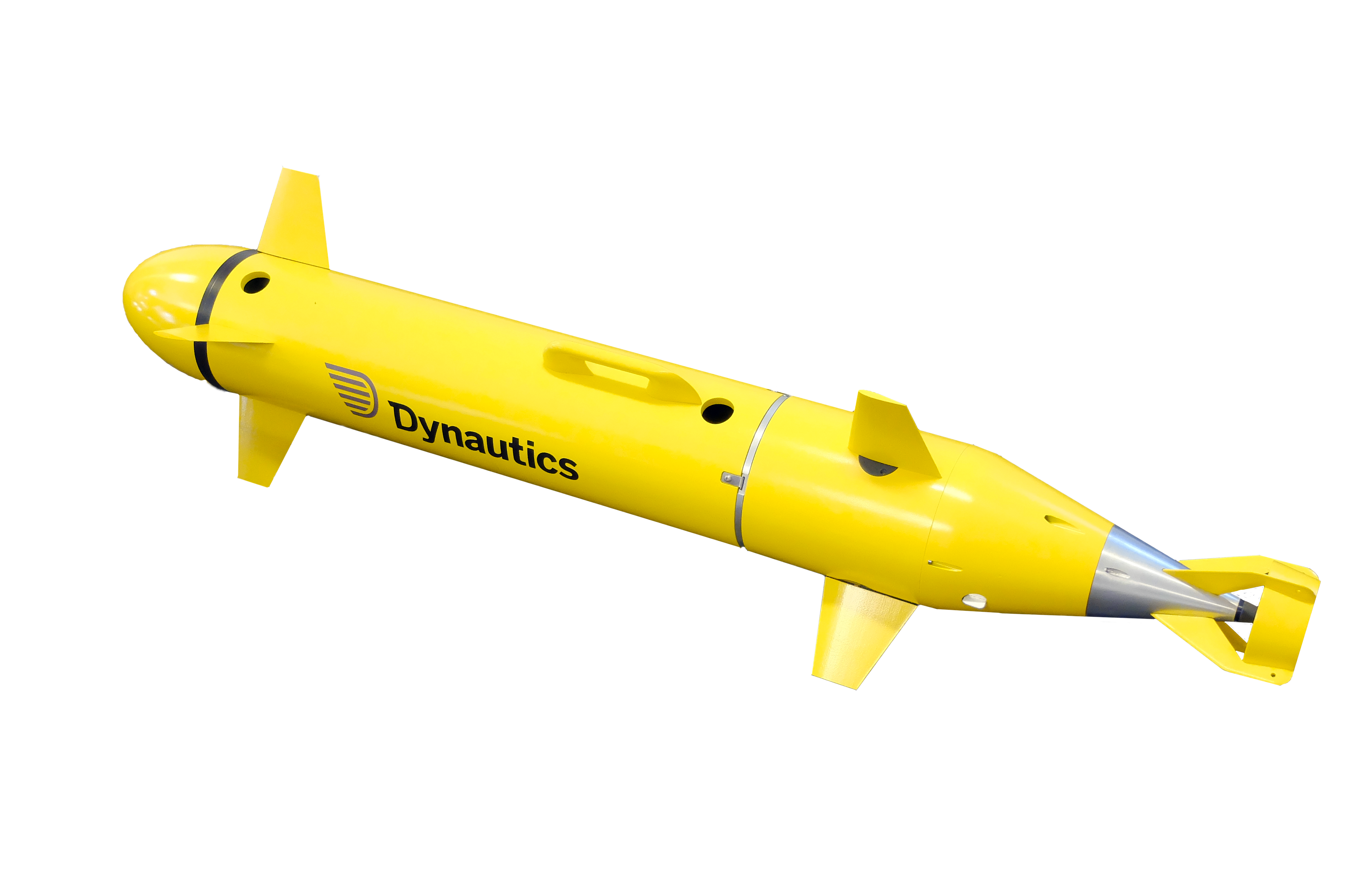

VCS for surface-submersible assault craft

Advanced maritime technology specialists, Subsea Craft, approached Dynautics to collaborate on the vessel control system for VICTA, the company’s next-generation maritime payload delivery platform which is capable of both surface and sub-surface maritime manoeuvres. Dynautics developed a customised control system for Subsea Craft based on its commercially proven SPECTRE autopilot technology, enhancing it with the SSC team to provide a system that is adapted to the complex requirements of hybrid surface and subsurface operations. Read more here.

“Controlling a prototype vessel such as Subsea Craft’s VICTA is the kind of challenge that the Dynautics team thrives on. It requires a deep understanding of vessel systems, subsystems and vessel dynamics, the development of complex control algorithms and a strong collaborative effort.”

Carl Reynaud, Dynautics

Triple engine control for Singapore Navy

Dynautics is a Mercury Marine dealer, giving us direct access to the company’s G3 engine set up software which is a critical factor in calibrating and optimising engine performance. In 2021, we had an opportunity to work on a triple Mercury engine (900hp) VCS for the Republic of Singapore Navy’s uncrewed security and surveillance craft.

It was a project with a tight timeframe, but by leveraging our experience with Mercury’s control protocol we were able to deliver our MK4 autopilot with Mercury interface module, remote control handset, wiring harness and Dynautics Remote Control Windows (RCW) application for remote route planning. All equipment was fully installed, calibrated and subject to sea trials in time for the Navy’s mission.

From clouds to waves with SPECTRE

ALTI serves the civil and military sectors with UAVs (unmanned aerial vehicles) for commercial and industrial applications. In 2022, the ALTI team embarked on a mission to bring their 10 years of experience and hard-won expertise on unmanned aircraft operations around the world to the design of a marine USV.

The team needed a control solution that they could fit themselves. Dynautics delivered a SPECTRE MK4 VCS, complete with wiring harness, interfaces and all necessary components that was ready to install. This plug and play solution dovetailed into ALTI’s existing communications system, giving the team a clear development and delivery path. Diagnostics took place remotely to progress the retrofit installation. Read the case study.

Royal Navy vessel conversions

In its drive to leverage autonomous technology in the future of naval operations, the UK’s Royal Navy is converting some of its vessels to have unmanned functionality. This cost-effective development approach allows them to make use of commercial electronics and low NRE (non-recurring engineering) costs, speeding up the time it takes to get uncrewed craft operational.

The Royal Navy has, to date, placed two VCS orders with Dynautics. Dr Alison Little, senior project engineer at Dynautics (pictured), developed custom vessel control firmware for their unique behaviour requirements. Dynautics’ marine simulators were also used to reduce the development cycle and time to launch.

“Customers who have very specific operational needs make my job incredibly interesting. The team here thrives on solving technically demanding control problems. The Royal Navy needed very specific behaviour and I was able to simulate their requirement and code it quickly, which was incredibly satisfying.” Dr Alison Little, Dynautics

Precise drive control for RC Dock Engineering

Netherlands-based RC Dock Engineering enlisted Dynautics for the remote control of a 12m catamaran vessel, the first of 20 new remotely controlled unmanned workboats developed by the company, with azimuth thrusters and twin water jets.

As well as designing the VCS using SPECTRE autopilot, Dynautics also advised on overall system architecture, design and the purchase of ancillary parts. We developed custom CAN communication firmware to provide precise control of the drive system and collision avoidance software was optimised with radar partners Simrad and Cambridge Pixel.

With RC Dock Engineering’s new hull design, transmission and power management arrangement, agility and collaboration were key on this project. The catamaran was later granted RINA class approval. These vessels are able to conduct remotely controlled unmanned operations in areas such as offshore survey and subsea inspection, maintenance and repair.

Pushing boundaries with SEA-KIT

SEA-KIT International is a leading designer and builder of USVs with a range of applications across the offshore, survey, research, defence and security sectors.

In August 2020, SEA-KIT’s USV ‘Maxlimer’ took part in a collaborative Atlantic survey project, co-funded by the UK Space Agency. The project was designed to demonstrate true, over-the-horizon survey capability, testing cutting-edge, innovative technologies to survey unexplored or to-date inadequately surveyed ocean frontiers. The USV spent 22 days offshore, completing survey operations off the European continental shelf.

During the mission SEA-KIT’s ‘Maxlimer’ travelled over 1200 nautical miles and mapped over 400 square miles of previously uncharted ocean floor. Dynautics provided 24/7 project support to SEA-KIT’s Remote Operation Centre in Essex, UK.

“Dynautics proved to be a very capable and trustworthy, assisting us in the development of our product, bringing a wealth of experience and showing real commitment to meet deadlines during the pandemic.” Peter Walker, Director of Technology at SEA-KIT