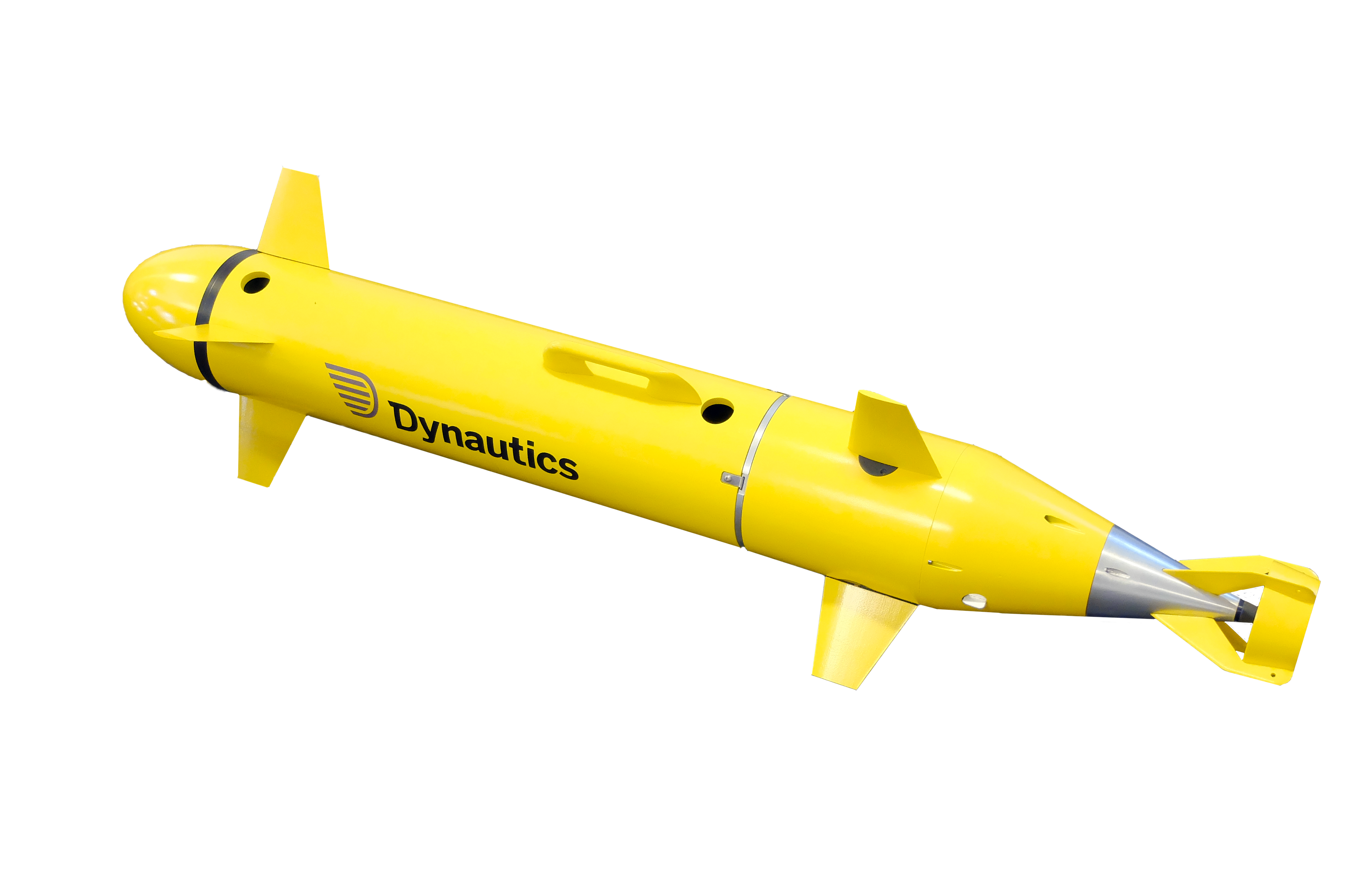

Dynautics provides intelligent marine control systems for USVs (uncrewed surface vessels) and subsea vehicles.

We design, manufacture and supply robust and reliable autopilot, remote control, navigation, communication and power management systems, using logic, precision and scientific integrity to solve the most complex challenges.

Dynautics is a trusted technology partner for uncrewed marine missions in offshore energy and mining, oceanography, marine transport and the defence and security sector. Thousands of miles have been successfully navigated using our reliable and robust vessel control technologies.

As co-authors of the Marine Autonomous Surface Ships – UK Code of Practice, we are actively helping to define the route towards marine vehicle autonomy.

Company Timeline

Professional Affiliations

Helping you deliver

Dynautics is a trusted technology partner across many marine sectors, including offshore energy and mining, oceanography, marine transport and defence and security. We use logic, precision and scientific integrity to reduce time to launch and ensure maximum reliability.

At the start of the design process, our marine simulator tools determine the most effective hull design and propulsion types, positions and characteristics. These simulators are proven in reducing the time to sea trials and mission acceptance, both crucial mission parameters.

We leverage our on-water experience to verify performance during commissioning and remotely monitor characteristics and modify variables, such as power consumption, to fine tune and meet requirements.

With 20+ years’ experience of scientific and engineering rigour in vehicle control algorithm development and associated electronics, our technical leadership is supported through simulation tools and authorship of marine autopilot heading and track control standards (IEC62065).

Meet the Team

Careers

Dynautics offers a dynamic team orientated work place. We have demanding clients who expect a high level of integrity, innovation and delivery. If you have the technical skills and drive in either hardware, firmware or software engineering disciplines we would like to hear from you.

Please send speculative enquiries to info@dynautics.com

Why us

We understand that every uncrewed vessel presents a unique set of challenges and that sea trials are expensive and demanding. Dynautics has a proven track record in vehicle design collaborations. We focus on mission goals, tailoring our services and leveraging our team’s expertise to reduce time to launch.