CASE STUDY: Dynautics has provided an autopilot solution for HydroSurv’s new, rim-driven thruster USV design. HydroSurv is a global provider of Uncrewed Surface Vehicle (USV) platforms for hydrographic, geophysical and oceanographic survey. The company, based in Exeter, United Kingdom, offers a range of electric and hybrid USVs from 2.5 to 6 metres for inland, nearshore and offshore survey operations.

In 2024, HydroSurv introduced its REAV-47 multi-purpose USV to meet growing customer demand for small to midsize seagoing USVs. The battery-hybrid REAV-47 is a compact, high-performance vessel for nearshore survey deployment, offering 90-hour endurance and featuring new rim-driven thruster propulsion technology from Netherlands-based Rim Drive Technology (RDT).

Having worked for six years with Dynautics on autopilot systems for other vessels in their range, HydroSurv approached the team again for the development and installation of updated autopilot technology to drive this new thruster type.

Challenges

Rim-driven thruster designs have advanced significantly over the past two decades, with new models giving powerful leverage and high torque at lower speeds than conventional motors. The hubless design of the impellers also minimises friction, which improves efficiency and reduces noise for electrically propelled boats. HydroSurv selected RDT propulsion for the new REAV-47 to reduce the risk of weed or fishing line entanglement, or tether fouling when towing instruments or hosting tethered ROV platforms – for which the company needed a customised autopilot solution.

Extensive experience in the development of CAN bus-based interfaces was critical to project success, and the system needed to be of modular design, so that the new interface could be installed without impacting the existing control system. HydroSurv was confident that Dynautics could deliver a tested and proven solution within its tight timescale.

Approach

Dynautics designs in a modular way and has worked extensively on the development of CAN bus interfaces. As with all its projects, the company made extensive use of automated simulation and testing, so that the new control system was thoroughly trialled prior to delivery to HydroSurv.

“It was a pleasure to work on yet another USV project with HydroSurv. The combination of the new thruster with independent steering gives the company another very capable craft. The REAV-47 is inherently scalable and will make a valuable addition to HydroSurv’s already comprehensive range of USV technology.” Henry Robinson, Dynautics CEO

Dynautics created a test environment to run the thruster in its laboratory, with RDT helpfully providing comprehensive information on their product. Dynautics conducted inhouse water tank testing prior to planned sea trials by HydroSurv using twin thrusters on the vessel itself.

Solution

Dynautics delivered a fast turnaround solution with which to integrate new rim-driven thruster technology into its long-term client HydroSurv’s vessels. The solution dovetailed into HydroSurv’s existing systems, giving the team a clear development and delivery path to install the technology on future vessels, including the smaller REAV-25, developed to align with MGN 702 MiniMASS Code, and sharing much of the same technology as the REAV-47.

“Our partnership with Dynautics has been instrumental to HydroSurv’s product development journey since we entered the USV market in 2019. The third-generation REAV-47 and REAV-25 platforms are the result of close collaboration with our customers and draw on over five years of experience in delivering USV solutions that drive immediate value for survey contractors. We’re excited for a strong pipeline of USV deliveries in 2025, with Dynautics playing a key role in supporting this next phase of deployment.” David Hull, HydroSurv CEO

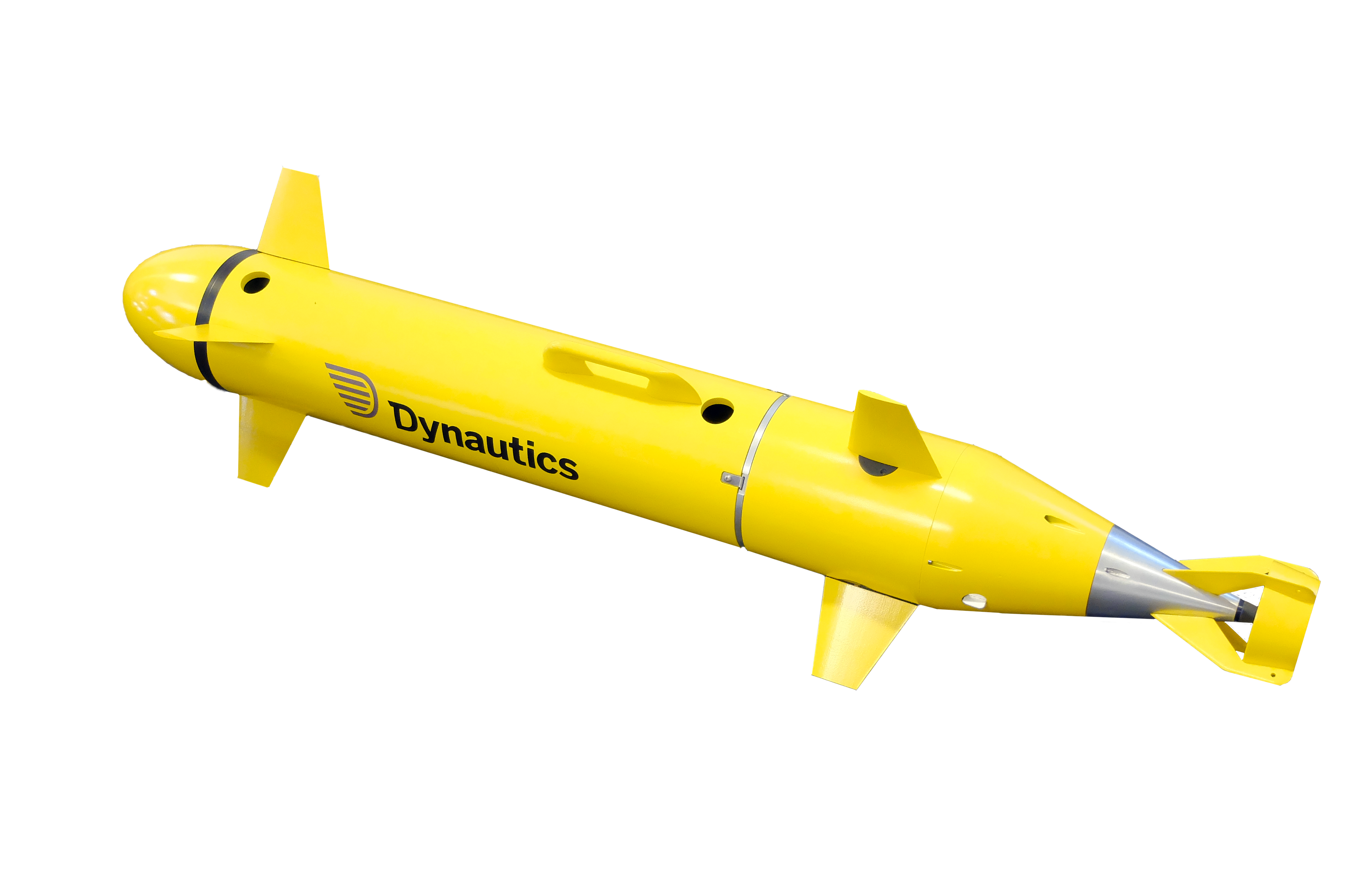

Image courtesy of Nordic USV A/S.